REINFORCING BAR

DEFORMED REBAR

N grade deformed reinforcement bar is the most commonly used rebar product in construction.

ROUND REBAR

250 MPa grade round steel bar, used in a range of concrete and building applications.

GALVANISED REBAR

Our standard grade N rebar, with a galvanised protective coating barrier from corrosive elements.

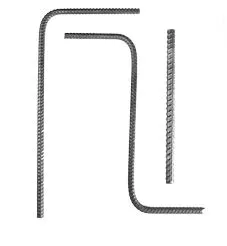

STOCK REBAR

We stock a range of high demand cut and bent rebar in a selection of shapes and sizes.

RELIABLE QUALITY

We laboratory test our reinforcing bar to

guarantee quality steel every time

FE 550 D Rebars are used to make Heavy Structures such as bridges and structures that require a high load bearing capacity. They are also used in High Rise buildings due to their load bearing capacity and ductility.

BuildQ TMT FE 550 D Rebars offer much more of everything. Be it strength, durability, ductility or bonding with concrete, BuildQ TMT offers best quality FE 550 D Steel Rebars.

STRENGTH

BuildQ TMT 550 D grade rebars with minimum Yeild strength of 550 ensures extra load carrying capacity in comparison to 500 D grade with minimum Yeild strength of 550.

FLEXIBILITY

High quality TMT bars manufactured in fully integrated steel plant ensures minimum UTS/Ys ratio of >=1.15 . Higher gap between Ys and UTS results in higher ductility of Rebars.

SAVINGS

Additional load carrying capacity of BuildQ TMT rebars leads to fewer number of rebars or reduced diameter results in upto 6% saving on steel quantity.

FE550D

| IS:1786 | BuildQ TMT Fe550D | |

| Chemical Properties | Fe550D | Fe550D |

| %Carbon (max) | .25 | .15 -.22 |

| %Sulphur (s)(max) | .040 | .025 -.035 |

| %Phosphorus (P) (max) | .040 | .025 -.035 |

| % S & P (max) | 0.075.25 | .070(max) |

| IS:1786 | BuildQ TMT Fe550D | |

| Mechanical Properties | Fe550D | Fe550D |

| Yield Stress | 550 | 560-600 |

| %Elongation (min) | 14. | 16-20 |

| TS/YS | >1.08 | 1.15-1.20 |

| Total Elongation | 5 | 6-8 |

CRS

CRS Grade TMT Rebars are typically used in coastal areas where there is high salinity and acid content in the air. Corrosion resistant elements such as Copper, Chromium and Phosphorous are added to make BuildQ TMT Bars corrosion free. This makes BuildQ TMT Bars suitable for use in coastal areas and also in construction of Bridges and Dams.

TECHNOLOGY:

| BuildQ TMT Fe550D CRS | |

| Chemical Properties | Fe550D |

| %Carbon (max) | .15 (Max) |

| %Sulphur (s)(max) | .040 (Max) |

| %Phosphorus (P) (max) | .085 to .100 |

| % Manganese (Mn) | .55 to .65 |

| % Silicon (Si) | .15 |

| % Chromium (Cr) | .20 to .30 |

| % Copper (Cu) | .15 to .25 |

| % S & P (max) | .070 (max) |

| IS:1786 | BuildQ TMT Fe550D | |

| Mechanical Properties | Fe550D | Fe550D |

| Yield Stress | 550 | 560-600 |

| %Elongation (min) | 14.5 | 16-20 |

| TS/YS | >1.08 | 1.15-1.20 |

| Total Elongation | 5 | 6-8 |

BuildQ TMT CRS Bars are produced in state of the art production line by using corrosion resistant elements like Copper, Chromium and Phosphorous in right proportions.

The state of the art Integrated Steel Plant enables us to control the quality of the CRS Grade Rebars consistently. BuildQ TMT CRS Rebars are made from billets manufactured in our plant using top quality sponge iron. Sponge iron is produced using iron ore from our own mines in Chhattisgarh. Corrosion resistant elements like copper, phosphorous and chromium are added in right proportions to make the steel corrosion resistant. The Thermo-mechanically Treated Bars produced using Thermax Quenching system provides excellent mechanical properties and provide high strength and ductility.

BuildQ TMT CRS Rebars have passed rigorous testing conditions like exposure to salt water, various atmospheric conditions and comply to IS: 1786-2008 specifications.